StepbyStep Splicing Process

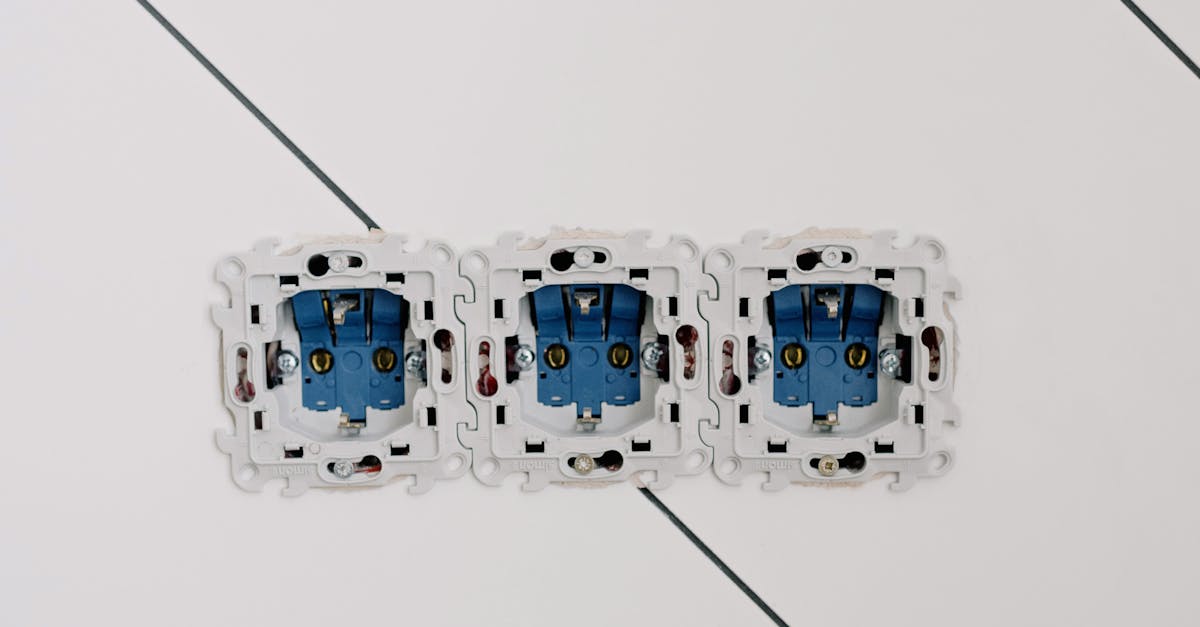

Splicing a gas line requires careful planning and execution to ensure safety and compliance with regulations. Start by gathering all necessary tools and materials, including a suitable splice kit, pipe cutter, and safety gear. Before beginning the splicing process, it’s essential to turn off the gas supply and relieve any pressure in the line. Locate the damaged section of the gas line and mark where the splice will occur. Properly cut the pipe using a pipe cutter, making sure the ends are smooth and free from debris.

Once the area is prepared, the next step is to insert the splice fitting into the cut ends of the gas line. Ensure that it fits snugly and is aligned correctly. Depending on the type of pipe, you may need to use specific adhesives or clamps to secure the connection. After the splice is connected, turn the gas supply back on and check for leaks using a soapy water solution. If you feel uncertain about any step during the process or prefer professional assistance, searching for "gas line installation and repair near me" can help you find qualified experts in your area.

Detailed Instructions for Splicing a Gas Line

Before attempting to splice a gas line, ensure you have the proper tools and materials ready. Begin by turning off the gas supply to the affected line. Locate the section that needs splicing and carefully cut out the damaged segment using a pipe cutter. Smooth the edges of the remaining pipe to eliminate any sharp parts that could compromise the connection. Once the area is prepared, insert a suitable splice connector, ensuring it matches the diameter of the pipe. Secure it tightly to prevent leaks, using the appropriate method for the type of connector you are utilizing.

After the splice is in place, it is crucial to check for leaks. Apply a soap and water solution over the newly connected area. Bubbles indicate a gas leak, requiring immediate attention. If you are uncertain about your ability to perform the work safely, search for “Gas line installation and repair near me” to find qualified professionals in your area. They can provide assistance and ensure the job is completed to code, minimizing risks associated with improper installation.

Potential Risks Involved

Working with gas lines carries significant risks that can pose serious dangers to both individuals and property. Even a small mistake during the splicing process can lead to leaks, resulting in potentially explosive situations. The highly flammable nature of gas means that improper handling can create an environment primed for disaster. Individuals should be aware of the signs of a gas leak, such as a distinctive smell or hissing sounds, and take immediate action if any are detected.

In addition to the immediate risks, there are long-term implications of improperly spliced gas lines. Gas leaks can lead to health risks, including carbon monoxide poisoning, which can occur due to inadequate ventilation of burning gas. The consequences of such negligence can be severe, leading to property damage or personal injury. If there's uncertainty about undertaking this task, searching for “gas line installation and repair near me” can connect you with qualified professionals, ensuring the work is conducted safely and correctly.

Common Hazards of Gas Line Manipulation

Manipulating gas lines carries several inherent risks that can have serious consequences. Even minor mistakes can lead to gas leaks, which pose immediate dangers such as explosions or health risks from inhalation. Tools designed for cutting or splicing can create sparks. Additionally, improper sealing of connections can result in harmful emissions. Addressing these hazards requires a keen awareness of safety protocols and the right equipment.

Another significant concern is the potential for physical harm during any gas line alteration. Sharp tools can cause personal injury, while working in confined spaces may lead to accidents or falls. It’s crucial to monitor the environment for gas accumulation, especially in enclosed areas. Individuals should always consider reaching out for professional assistance, like searching for gas line installation and repair near me, to mitigate these dangers effectively.

Professional Help vs. DIY

When considering whether to tackle gas line work yourself or hire a professional, it's essential to weigh your experience against the potential risks. Gas lines require precise handling and specialized knowledge to ensure safety and compliance with local codes. A simple mistake during installation or splicing can lead to dangerous leaks or even explosions. For those without training, the risks often outweigh the savings associated with DIY projects.

Professional services can provide peace of mind, as they possess the necessary tools and expertise to perform gas line tasks safely. Finding options for "gas line installation and repair near me" can offer convenient solutions tailored to your needs. Professionals are equipped not only with the technical skills but also with the appropriate permits and knowledge of regulatory standards, ensuring the job is done safely and correctly.

When to Call in a Gas Line Specialist

Recognizing when to call in a specialist is crucial for ensuring safety and compliance with local regulations. If you notice gas leaks, unusual smells, or inconsistent gas supply, it is essential to seek professional assistance immediately. Gas line installation and repair near me can help address these issues safely. Attempting to fix problems without the appropriate training or tools can lead to hazardous situations, including fires or explosions.

Even if the problem appears minor, the complexities of gas line systems often require expert knowledge. A trained technician can assess the situation accurately and implement solutions that meet safety standards. They can also provide guidance on maintenance and preventive measures, ensuring your gas line operates efficiently. Prioritizing safety should always be the first step when dealing with gas line issues.

FAQS

Is it legal to splice a gas line yourself?

In many areas, splicing a gas line is regulated by law, and it is often required to be performed by a licensed professional. Always check local regulations before attempting any gas line work.

What tools do I need to splice a gas line?

The tools needed can vary, but generally include a pipe cutter, wrenches, thread seal tape, gas line fittings, and safety equipment such as gloves and goggles.

What are the signs of a gas line leak?

Common signs of a gas line leak include a distinct sulfur smell (like rotten eggs), hissing or whistling sounds near the line, and dead or dying vegetation in the area around the line.

How can I ensure safety while working on a gas line?

Always turn off the gas supply before starting any work, use proper tools and safety equipment, work in a well-ventilated area, and consider hiring a professional if you are unsure about the process.

What should I do if I suspect a gas line leak after splicing?

If you suspect a gas line leak, evacuate the area immediately, avoid using any electrical devices or open flames, and contact your gas company or a professional gas line technician right away.